HENAN JINHE INDUSTRY CO.,LTD

[Henan,China]

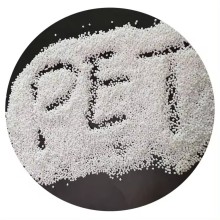

Business Type: Manufacturer , Distributor/Wholesaler , Agent , Trade Company Main Markets: Africa , Asia , East Europe , Middle East , Oceania , Worldwide , Americas , Caribbean , Other Markets , West Europe Exporter: 71% - 80% Certs: ISO9001, MSDS, Test Report Description: PET Resin IV 0.83,Oil Bottle Usage PET Resin,Injection Molding Grade PET Resin

- Home

-

Products

- Pigment&Dye >

- Resin >

- Detergent >

- ACID >

- Abrasive >

- Water Treatment >

- Plasticizer >

- Anti-COVID 19 Product >

- Anhydrous Aluminium Chloride

- Pharmaceutical Intermediate

- Basic Chrome Sulphate

- Potassium Hydroxide

- Sodium Hydrosulfite

- Zeolite

- Propylene Glycol

- Copper Sulphate

- Fumed Silica

- MELAMINE

- Chemical Additives >

- EVA Resin

- Plastic Masterbatch

- Acesulfame K

- PE WAX

- Methylene Chloride

- About Us

- News

- Video

- Contact

- Send Inquiry