Because of its fine particle size, PVC Paste Resin is like talcum powder and has no fluidity. PVC paste Resin is mixed with Plasticizer to form a stable suspension after stirring, that is to say, PVC paste, or PVC plasticizer paste, PVC sol, and it is in this form that people are used to process the final products. In the paste making process, various fillers, diluents, heat stabilizers, foaming agents and light stabilizers are added according to the needs of different products.

PVC paste resin is a branch of Pvc Resin. PVC paste resin is named for its highly dispersed powder used in paste processing. Because of its excellent pasting performance and good dispersion, it is mainly used in the soft material field of PVC Resin. It can be applied to coating, dipping, spraying, foaming and other processing technology, and is widely used in the fields of artificial leather, decorative materials, floor leather, wall paper, industrial conveyor belt, sports ground, coatings, adhesives, toys, disposable gloves, daily decorative materials, electrical instruments, electrical tools and many other materials and products.

PVC paste resin processing has the advantages of cheap equipment, simple and cheap processing mold, can be made into special shape, easy foaming, less heating times, and can be produced in a small amount and variety. Therefore, it is widely used in artificial leather, floor leather, toys, wallpaper, automotive interior materials and other hard products, and has a broad market application prospect.

How to choose PVC paste resin?

With the deepening of the application and development of PVC paste resin in China, the market demand for PVC paste resin at home and abroad is gradually increasing. In recent years, some structural changes have taken place in the downstream products of PVC paste resin in the industry, from the original glove material and leather material dominated industry to the new industry, especially in automobile, construction, electronics, coatings, etc In terms of shoes, which aspects should downstream product enterprises pay attention to in the process of choosing paste resin?

First point

To select suitable polymerization process according to terminal products, there are two main polymerization methods of PVC paste resin in China, namely emulsion polymerization and micro suspension polymerization. Among them, emulsion polymerization PVC paste resin is mainly leather material, also known as large dish material. Micro suspension polymerization of PVC paste resin is also known as glove material.

Second point

To choose according to the mechanical properties of the end product, one of the criteria for measuring the degree of polymerization is to take the technical index of Anhui Tianchen paste resin as an example: PVC products with high degree of polymerization have relatively high mechanical strength, which are suitable for wear-resistant layer, tensile layer, hard surface layer and Matt layer, while PVC products with low degree of polymerization have relatively low mechanical strength.

Third point

According to the use, type and processing form of terminal products, the appropriate paste resin grades should be selected. Viscosity of paste resin products is an important choice index, for example, high foaming products choose paste resin products with relatively large viscosity and low gelatinization temperature, so as to control good foaming properties and uniform size distribution of foams. The product requirements paste viscosity, paste viscosity is generally required not to be too high, in order to facilitate processing.

Fourth point

The stability and degassing performance of plasticized paste should be considered. Only the plasticized paste with good stability can produce good paste products under the optimized process conditions; For the PVC paste that needs vacuum defoaming, it is required to have good degassing property.

in summary:

For most paste products, the general paste resin should be selected, which has the advantages of large batch production, wide application range, reliable and stable product quality, easy to master resin performance, relatively low price, mature processing technology and simple process optimization and adjustment. But for products with special requirements, you can choose the brand number of paste resin for special purpose. Although the application scope of these resins is not wide, and the price may be relatively higher, when they are used for their specified purposes, the effect is generally better than the general effect, and the performance and quality characteristics of the products can better meet the special requirements.

At present, there are several kinds of special paste resins in China, such as bright type, foaming type and extinction type.

Causes of foaming of PVC paste resin

PVC paste resin is widely used in artificial leather, soft trademark, wallpaper, industrial coatings and foam plastics and other industries. But the problem of foam produced in the process of making this PVC paste resin really makes the manufacturer extremely headache. Here are some problems that the production process will encounter.

1. When preparing dispersant

There is a stirring operation when dispersing agents are distributed, which results in a large amount of foam in the solution, which will not only lead to spillover and dispersant loss, but also affect the height of the liquid level.

2. Dispersant in polymerization

When the dispersant is polymerized, the surface tension of the dispersant will also produce foam (the "wet bubble") along with the stirring. The existence of the "wet bubble" will lead to VCM gas phase polymerization.

3. Discharge process of slurry

After the reaction, the slurry generally has to be discharged into the trough, and the unreacted gas must be removed. In this process, the discharge tank will be accompanied by many bubbles. The bubbles will follow the unreacted gas, which will lead to waste of materials and blockage of pipes.

So how to solve the problem of foaming?

Welcome to leave a message at the end of the article about your solution!

Frequently asked questions about PVC paste resin

1. Can ordinary PVC be made into PVC paste resin?

Answer: ordinary PVC can not be made into PVC paste resin.

2. What calcium powder does PVC paste resin add?

Answer: calcium carbonate powder is usually added in PVC paste resin.

3. What is the difference between PVC resin powder and PVC paste resin?

A: there are two main differences between the two

a. Physical state: PVC paste resin is white fine powder, while PVC resin is white fine particle;

b. Usage: PVC paste resin should be mixed with appropriate amount of plasticizer (DOP) to make it into plasticized paste (liquid). It is generally used in the manufacture of soft plastic products. PVC resin is used after granulation with appropriate amount of plasticizer, which is generally used in the manufacture of hard plastic products.

4. Which industries are PVC paste resins mainly used in?

A: it mainly includes: artificial leather industry, floor leather industry, glove material industry, wallpaper industry, toy industry, plastic dipping industry, conveyor belt industry and automobile decoration material industry.

5. The formula of PVC paste resin dip solution?

Answer: paste resin + stabilizer + plasticizer + viscosity regulator

6. What is the upstream raw material of PVC paste resin?

A: calcium carbide method: calcium carbide + hydrogen chloride; Ethylene process: Petroleum + chlorine

7. PVC paste resin with plasticizer mixing uneven, there is a small pimple is how to return a responsibility?

A: mixing speed is not fast, you can choose high-speed mixer mixing, if not solved, please contact the manufacturer's technical personnel to help you debug.

8. PVC paste resin and two octyl resin mixed viscosity is too high, how to do?

A: if the viscosity of PVC paste resin and dioctyl ester is too high after mixing, it is because the DOP is added less. Try to add more.

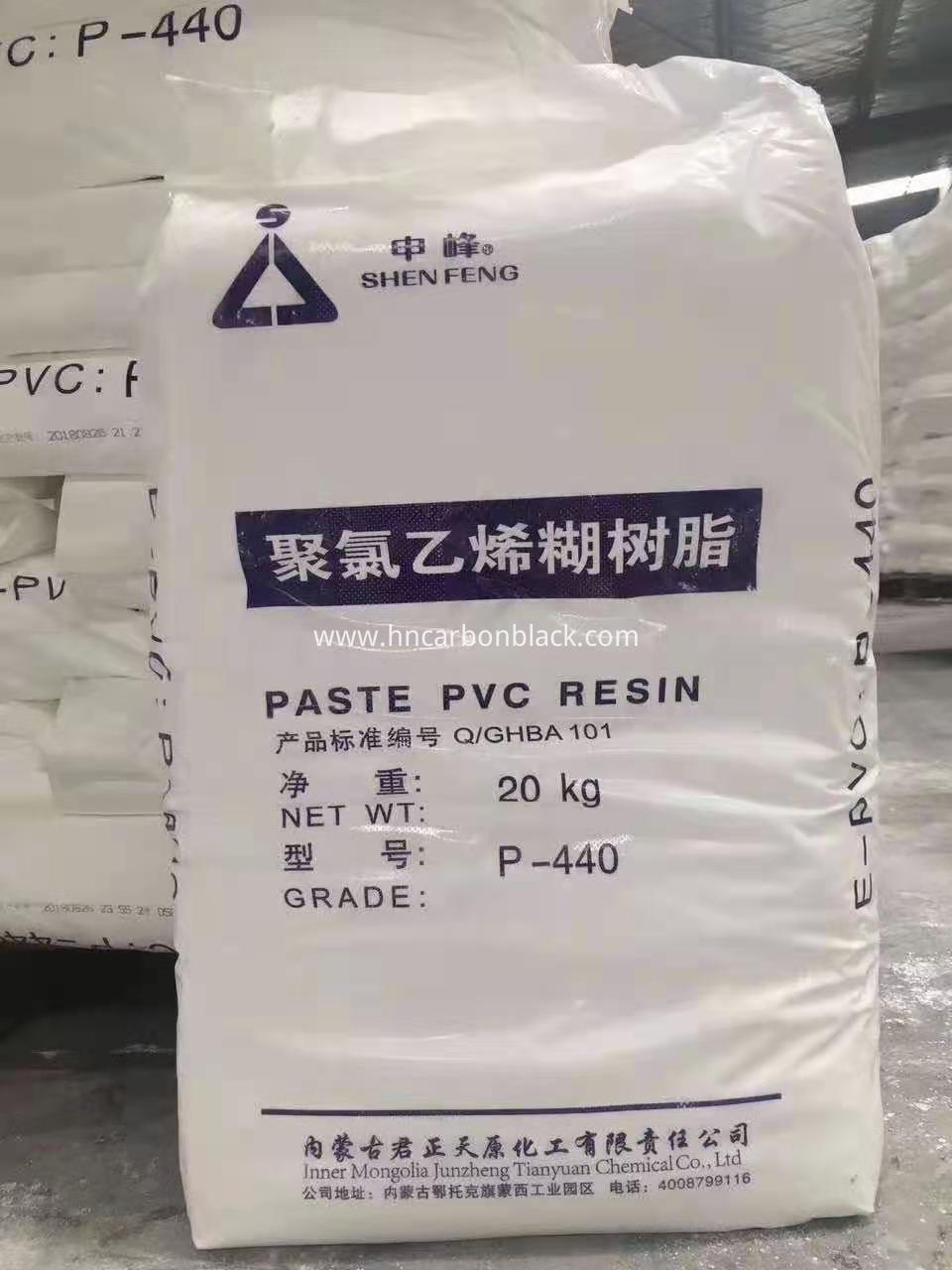

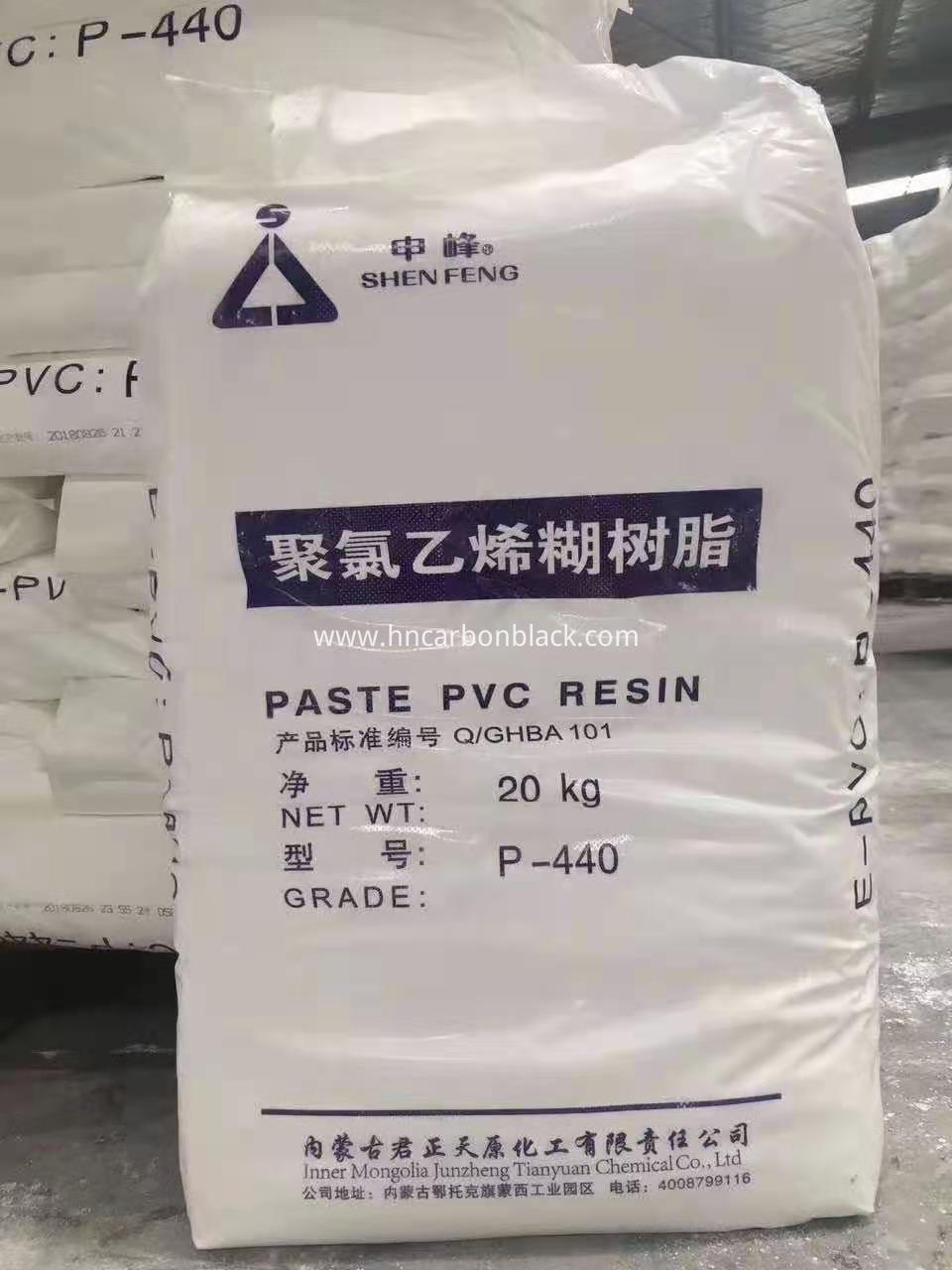

If you have more questions, please feel free to contact us. We provide all kinds of paste resins from various manufacturers in China, such as PVC paste resins p440, P450, pb1302, pb1156, pb1311, thp31, bpr-1069... With abundant inventory, favorable price and fast delivery speed.